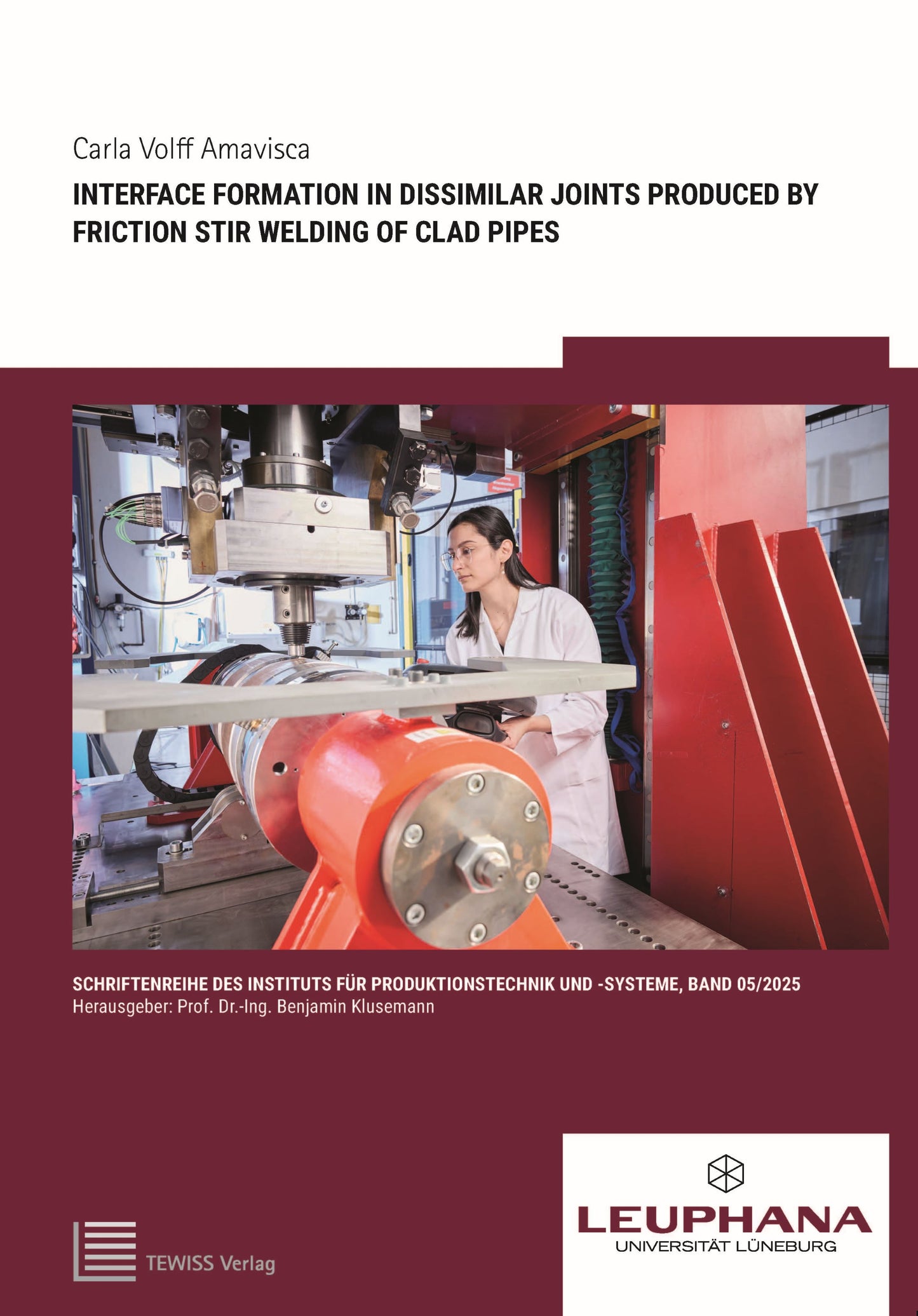

Interface formation in dissimilar joints produced by friction stir welding of clad pipes

Autor*in: Carla Volff Amavisca

ISBN: 978-3-69030-123-7

Dissertation, Leuphana Universität Lüneburg, 2025

Herausgeber*in der Reihe: Prof. Dr.-Ing. Benjamin Klusemann

Band-Nr.: IPTS 05/2025

Umfang: 127 Seiten, 60 Abbildungen

Schlagworte: Orbital FSW; Cladded pipe; API PSL2 X65 steel; Inconel 625; Microstructure

Kurzfassung: Pipelines in the oil and gas industry operate under severe conditions, facing high mechanical loads and corrosive environments. Their most critical regions are the circumferential welds, where conventional fusion-based techniques often lead to microstructural degradation, residual stresses, and brittle phases that can compromise reliability.

This work investigates orbital friction stir welding (FSW) as a solid-state alternative for joining clad pipes of API X65 steel with an Inconel 625 layer. By operating at lower temperatures and with reduced energy input, FSW minimizes the drawbacks of fusion welding while producing defect-free, high-strength joints in a single pass.

Comprehensive characterization, including advanced microscopy, diffraction, hardness testing, digital image correlation, and residual stress measurements, demonstrates how process parameters influence weld quality and microstructural evolution. The results show near-complete recrystallization of Inconel 625, bainitic refinement in X65 steel, enhanced hardness, and residual stress relief. Optimized welds surpassed theoretical strength predictions, with fractures occurring only in the base material, thereby confirming joint robustness.

This research establishes orbital FSW as a feasible technique for producing highperformance clad pipe welds, contributing to safer, more durable, and efficient solutions for offshore energy systems.