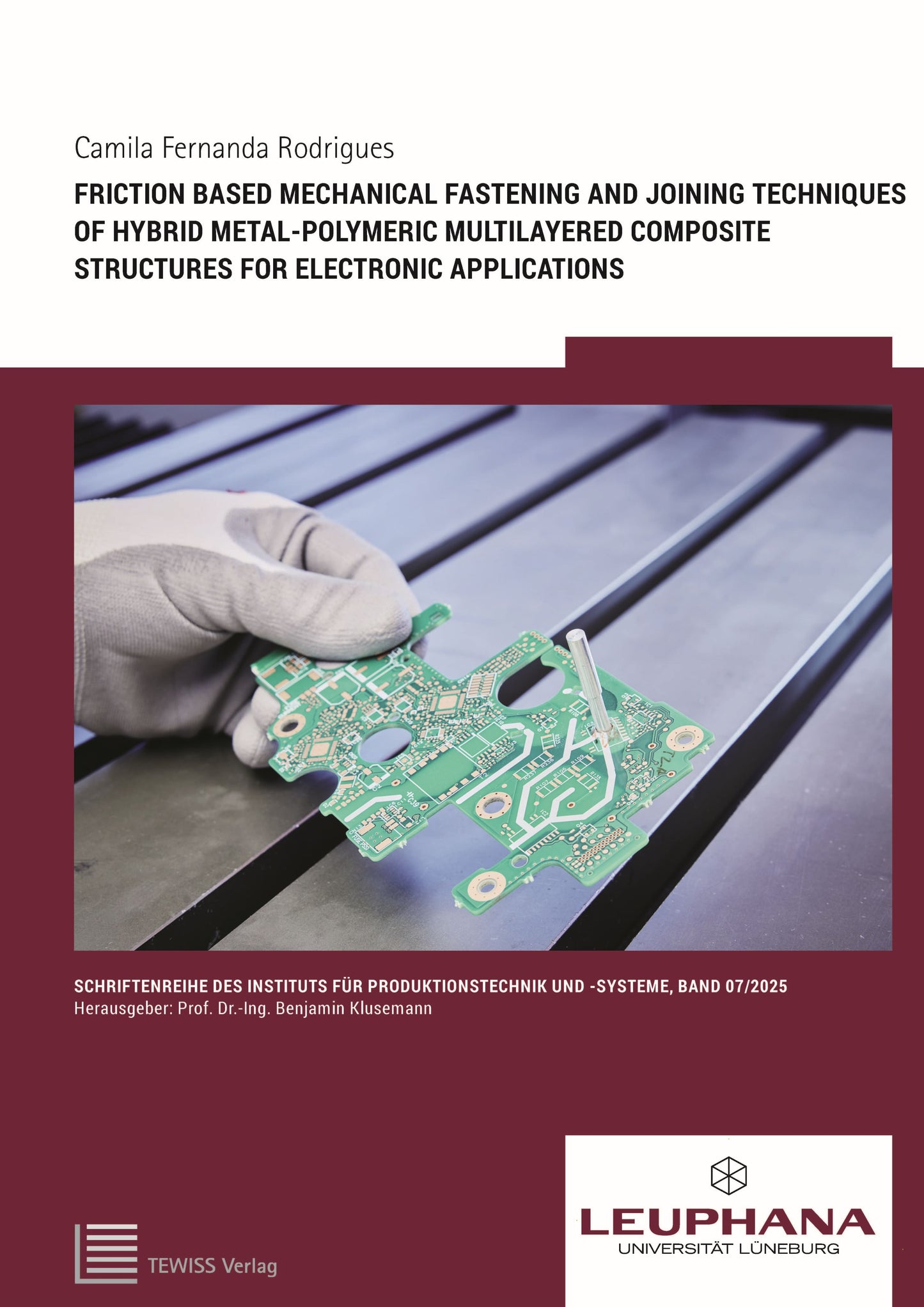

Friction based mechanical fastening and joining techniques of hybrid metal–polymeric multilayered composite structures for electronic applications

Autor*in: Camila Fernanda Rodrigues

ISBN: 978-3-69030-147-3

Dissertation, Leibniz Universität Hannover, 2025

Herausgeber*in der Reihe: Prof. Dr.-Ing. Benjamin Klusemann

Band-Nr.: IPTS 07/2025

Umfang: 132 Seiten, 44 Abbildungen

Schlagworte: FricRiveting, PCB assembly, FR4 substrates, joining

Kurzfassung: The growing demand for smaller, more efficient electronic devices is driving the need for innovative PCB joining techniques. Traditional methods are limited in terms of mechanical reliability and thermal stress. Friction riveting (FricRiveting) is emerging as a promising solderfree alternative.

This research project investigates the feasibility of using FricRiveting for PCB assembly, with a focus on optimizing process parameters and understanding joint performance. Joints were produced using AA-2024-T351 rivets and FR4 laminate. Various experimental techniques were employed to characterize the joints, including optical microscopy, infrared thermography, mechanical testing and advanced thermal analyses such as differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA).

The findings show that rivets can be effectively anchored within the FR4, provided the process temperature is kept below 360°C. However, excessive heat causes the epoxy resin to degrade, which has a negative impact on the long-term integrity and reliability of the joint. The study highlights rotational speed and friction force as crucial parameters for joint quality. In conclusion, FricRiveting shows great promise for PCB applications, offering a sustainable and robust joining method. However, further optimization is essential to mitigate the effects of thermal degradation and integrate the process into high-volume automated manufacturing lines.